How can the disc angle rotation be measured?

With this encoder, the displacement is obtained by counting the number of times that transitions occur between logical values “0” and “1”. This allows the transformation of physical quantities by converting the angular displacement variations into electrical type signal output that is translated into logical values by suitable electronics.

The counting of the number of transitions that occur in the (reflective / opaque and non-reflective / transparent) disc sectors is related to the concept of resolution.

The resolution may be defined as the smallest change in a quantity under measurement that causes a noticeable change in the corresponding outcome. In this case, the resolution of the disc corresponds to its minimum angular variation that causes a transition at the logical output level. As there are nine 0 to 1 transitions in a complete rotation of the disk.

What different types of encoders exist?

The most widely used classification refers to the type of movement (linear or rotary). In both cases they can be incremental, semi-absolute or absolute.

Incremental information is obtained by simply counting the pulses. Therefore, it depends on the previous state and the value of the transition. Its biggest drawback consists in the need for defining a starting position reference: this information is lost whenever the system is powered down or is turned off.

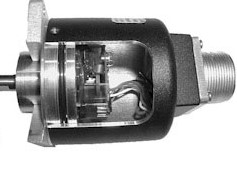

In contrast, in absolute encoders (of angular or linear type) each position is properly referenced with a unique code, Above Figure, corresponding to a unique pattern of bits in the various tracks. So, the position is always known and it is not necessary to define a reference if the system is powered down or is turned off.

The semi-absolute encoders are typically rotary and are used when it is necessary to measure displacements that exceed the measuring range of the absolute encoder. In this case it is necessary to use an additional procedure to count the number of disc turns during the measurement.

Credit by ;- https://instrumentationtools.com/encoder-working-principle/